Industrial Products

Composites are an outstanding choice of material for industrial products offering great advantages and excellent characteristics compared to other building materials.Parts are cost effective, have high flexing tolerance and have superior strength to weight ratio. They can be built to have resistance against corrosive environments including soils, salt water, U.V and chemicals. They are electrically non-conductive and versatile being able to withstand high pressures, temperatures, and loads. Composite products offer advanced finishes and great design flexibility.

Our team is experienced in producing industrial composite products for many industries including viticulture, horticulture, aquaculture, building, vehicle and marine.

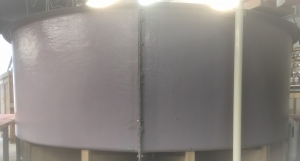

We have a large range of existing tanks moulds ready for production now. We are always happy to speak with you about making tanks or other composite products to you exact specifications.

Click here to view a full list of our stock tank moulds available for production immediately:

https://www.richmondfibreglass.com/wp-content/uploads/Website-Tank-List.pdf

Composite processes include –

Wet/hand layup places fiber layers onto an open mould then saturates the fibers with resin working it into the fabric. This method is ideal for small parts and repairs and areas on parts requiring additional strength.

Chopper gun layup places continuous strands of fibreglass pushed through a hand-held gun that both chops the strands and combines them with catalysed resin. The impregnated glass is shot onto the mould surface in whatever thickness the design requires. This process is fast and excellent for large parts, large production runs and is very economical.

Resin infusion – glass fabrics are placed into a mould then covered, resin is forced into the cavity which is under vacuum. This process allows for precise tolerances and detailed shaping of parts.

Carbon fibre strengthening offers high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion.

The smooth coating on fibreglass products called gel coat is very hard wearing and provides a low friction surface. It is ideal for use in harsh environments.